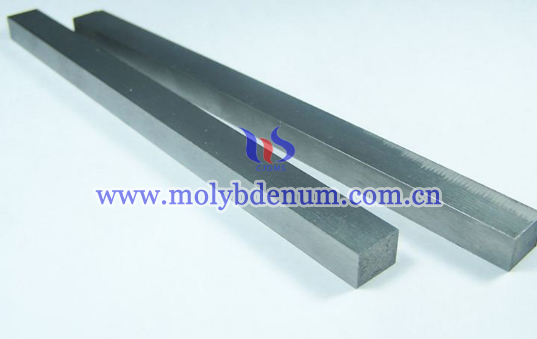

Molybdenum Copper Bar

Molybdenum bar is alloyed with copper with different proportion. The molybdenum copper composite materials are produced by the method of infiltration and are available with different copper shares, always ranging from 15% to 35%.

Typical Properties

| MoCu |

|

65/35 |

80/20 |

85/15 |

Molybdenum |

% |

65±3 |

80±2 |

85±2 |

Copper |

% |

35±3 |

20±2 |

15±2 |

Density |

g/cm3 |

9,73±0,2 |

9,9±0,2 |

10,0±0,2 |

Hardness |

HB2.5/62.5 |

120-150 |

130-160 |

130-160 |

CTE 20-100 °C |

10-6/K |

8,6 |

6,3 |

6,2 |

CTE 20-300 °C |

10-6/K |

9,2 |

6,4 |

6,3 |

CTE 20-450 °C |

10-6/K |

9,6 |

6,6 |

6,5 |

Elastic Modulus |

KN/mm2 |

210-250 |

220-260 |

220-260 |

Ultimate Tensile Strength |

N/mm2 |

>280 |

>300 |

>320 |

Yield Strength |

N/mm2 |

>270 |

>280 |

>300 |

Electrical Conductivity |

% IACS |

45 |

35 |

32 |

Electrical Resistiance |

mm2/m |

0,038 |

0,042 |

0,042 |

Thermal Conductivity |

W/mK |

≥170 |

≥150 |

≥145 |

Molybdenum copper bar is available in making switching contacts, construction elements for passive thermal management.